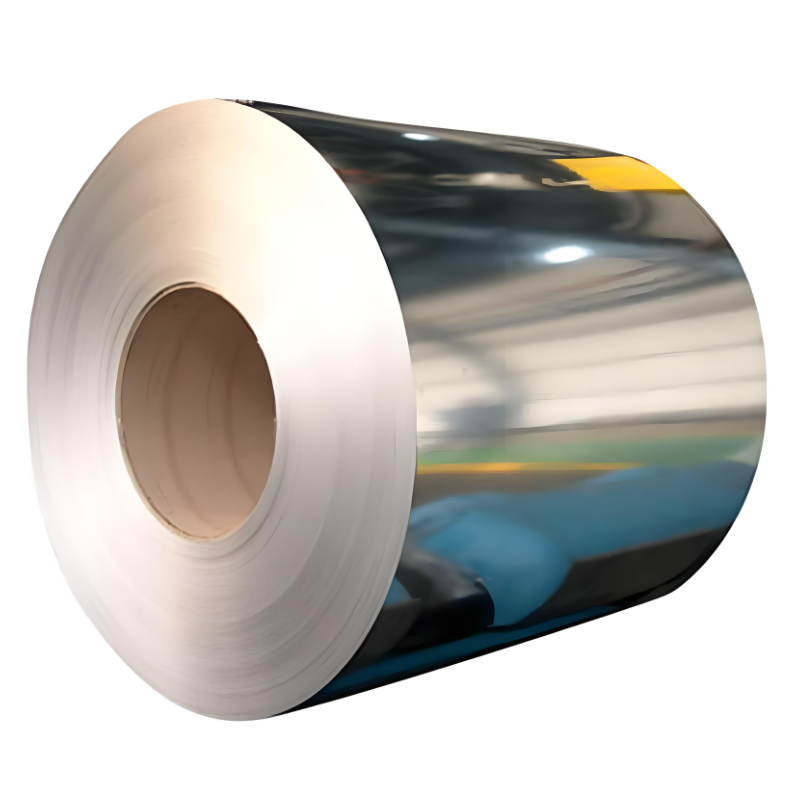

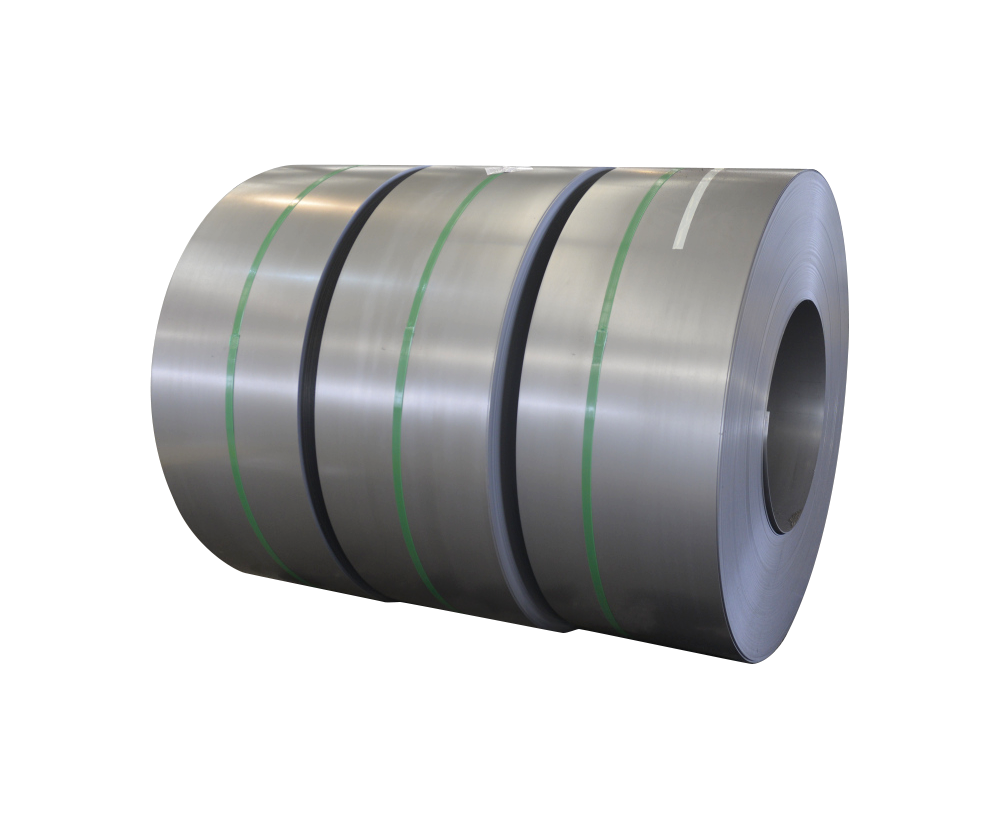

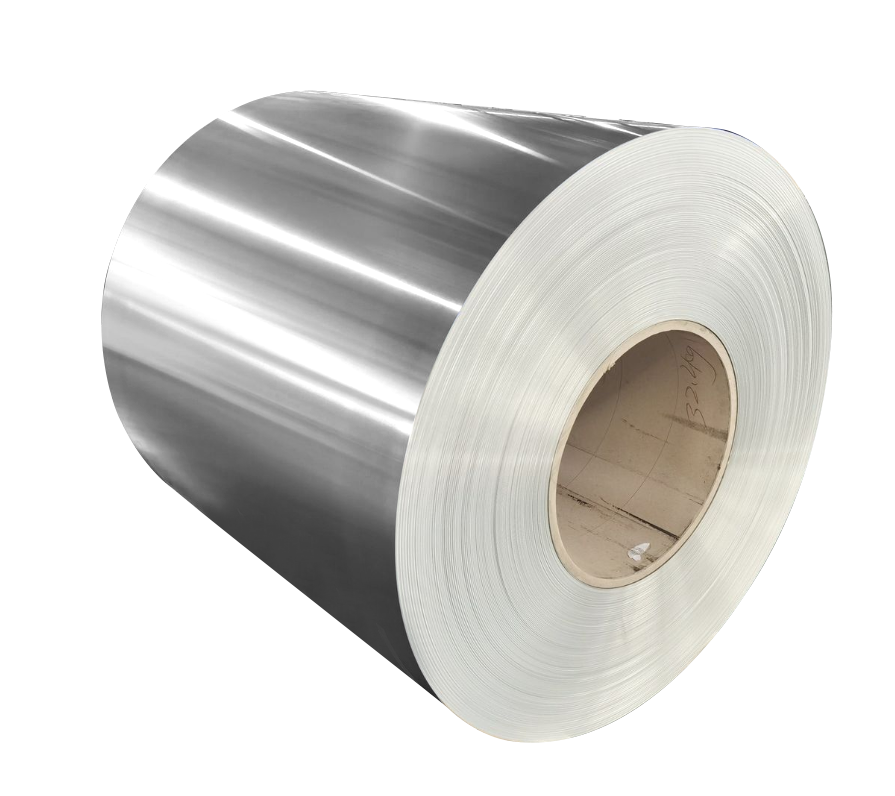

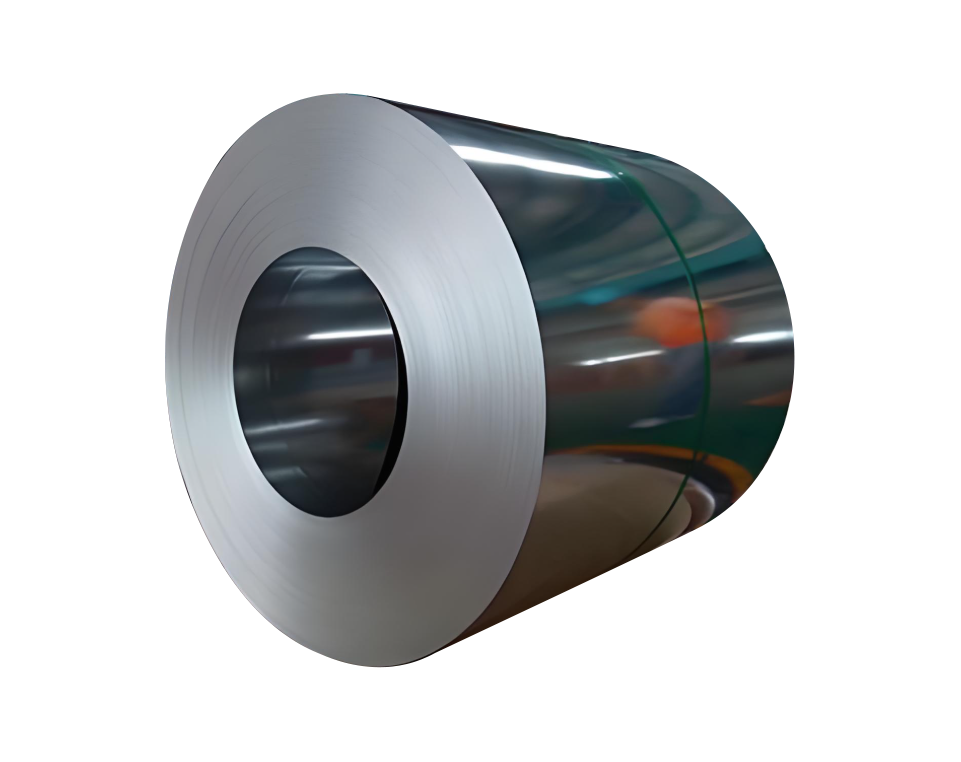

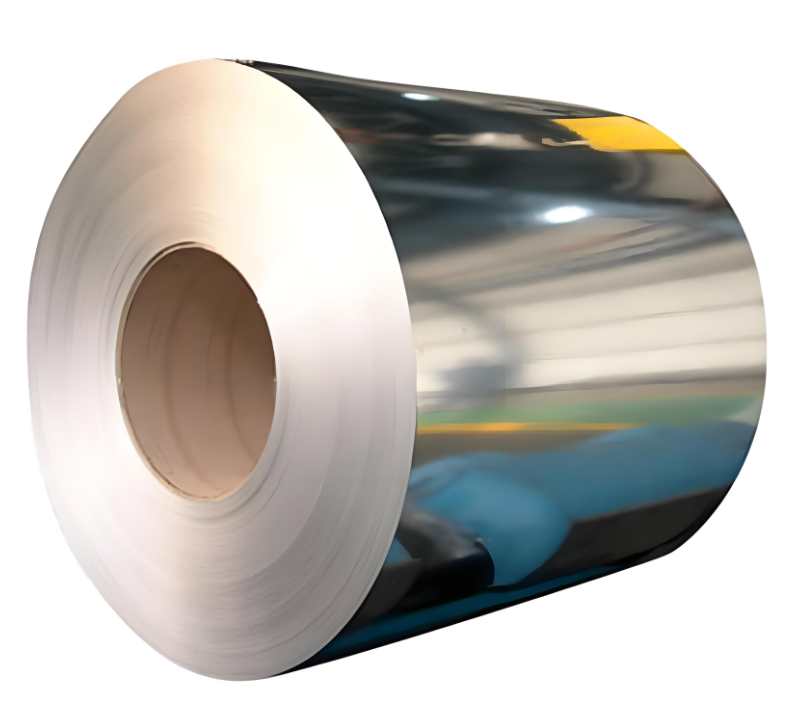

- MR T1-T5 BA,MR DR7-DR8M BA

- 0.135-0.5mm

- 600-1050mm

- Food Cans, Chemical Cans, General Cans, Aerosol Cans, Beverage Cans

Product Description

Applications for Tinplate (Galvanized Tinplate)

Tinplate (galvanized tinplate), renowned for its corrosion resistance, mechanical strength, and processing flexibility, is widely applied across multiple industries. Below are its core applications and technical highlights:

1. Food & Beverage Packaging

Core Applications:

Food Cans:

Used for tea cans, coffee cans, milk powder cans, and biscuit tins. Its sealing and barrier properties (blocking light, oxygen, and moisture) preserve freshness long-term, with vitamin C retention rates exceeding 90%.

Beverage Cans:

Suitable for juice, beer, and carbonated drink packaging. Supports high-pressure filling processes (e.g., aerosol cans) and offers diverse shapes (round, square, or custom) to meet personalized demands.

Technical Advantages:

Non-toxic tin coating complies with food safety standards (e.g., FDA), and its recyclability exceeds 80%, reducing environmental impact.

2. Industrial Manufacturing & Equipment

Automotive & Marine:

Automotive Parts:

Used in body frames, engine hoods, and exhaust pipes. High strength (tensile strength ≥350 MPa) and corrosion resistance (salt spray test ≥96 hours without rust) extend component lifespan.

Marine Components:

Bulkheads and deck structures withstand high-salt environments.

Machinery:

Valves, bearings, and heat exchangers leverage the tin layer’s heat resistance (≤315°C) and wear resistance.

3. Construction & Transportation

Architectural Decoration:

Envelope Structures:

Roof tiles, wall panels, and window frames excel in humid or high-temperature regions due to weather resistance.

Decorative Materials:

Guardrails, staircases, and billboards feature printed patterns for both functionality and aesthetics.

Transportation Infrastructure:

Highway guardrails, subway station canopies, and railway vehicle panels provide high-strength support and corrosion resistance.

4. Medical & Chemical Sectors

Medical Devices:

Surgical instruments, implants, and pharmaceutical equipment benefit from biocompatibility and chemical corrosion resistance.

Chemical Containers:

Storage tanks, pipelines, and valves resist acid/alkali corrosion, ensuring safe chemical handling.

5. Emerging Applications

New Energy & Electronics:

New Energy Vehicles:

Battery housings and charging pile structures utilize lightweight designs (low density) to meet weight reduction needs.

Electronics:

Phone/computer casings and heat sinks combine conductivity and electromagnetic shielding