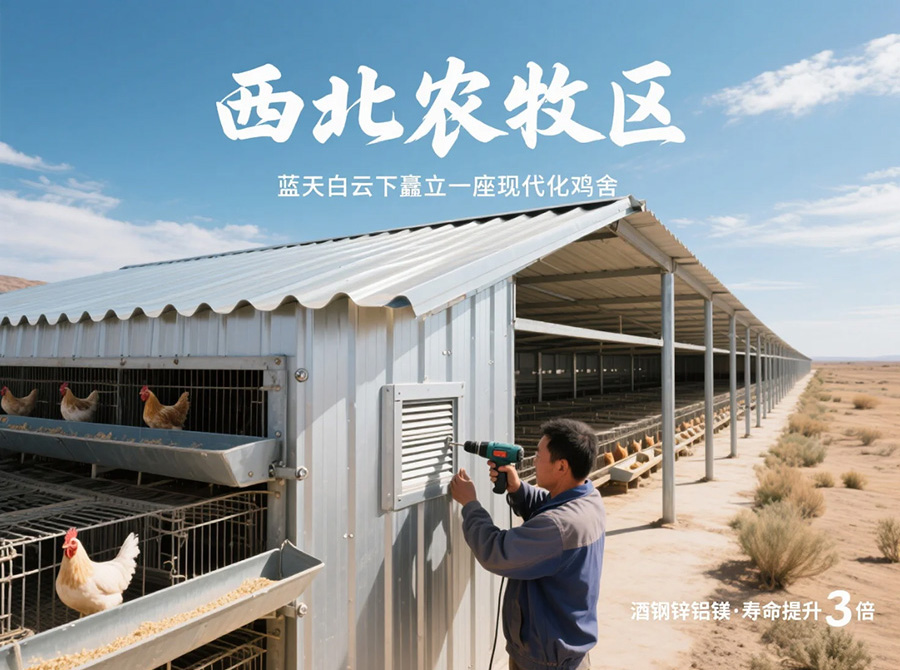

Jiangsu Huarida Group Secures Landmark Zn-Al-Mg Steel Order for Modern Poultry Farming

I. Project Signing: Huarida and JISCO Secure Northwest China Poultry Farm Order

With the strong support of Jiuquan Iron and Steel Group (JISCO), Jiangsu Huarida Group officially signed a Zn-Al-Mg steel supply agreement on March 20, 2025, for a large-scale modern poultry farm in a northwestern province. The initial order volume totals 2,000 tons, utilizing JISCO’s proprietary high-corrosion-resistant Zn-Al-Mg coated steel plates to construct intelligent farming facilities. These materials extend the lifespan of poultry houses by over 3× compared to traditional galvanized steel and reduce lifecycle maintenance costs by 40%.

Key Project Highlights:

Material Innovation:

JISCO’s Zn-Al-Mg steel features a Zn-Al-Mg-rare earth alloy coating (8–10× more corrosion-resistant than conventional galvanized steel). Its unique “self-healing” property automatically repairs processing damage, preventing rust spread—ideal for high-humidity, high-ammonia farm environments.

Lightweight Design:

Using 2.0mm-thick coated steel plates (180g/m² coating weight), the design achieves 15% weight reduction and 30% lower construction costs through high-strength steel structural optimization.

Smart Integration:

Equipped with Huarida’s AI-driven environmental monitoring system, the facilities dynamically regulate temperature, humidity, and ventilation, minimizing ammonia-induced corrosion risks while enhancing animal welfare.

II. Strategic Collaboration: Green Materials Empower Agricultural Modernization

1. Addressing Industry Pain Points

Traditional poultry farm steel structures, prone to corrosion from manure and humidity, require replacement every 5–8 years. JISCO’s Zn-Al-Mg steel extends durability to 20+ years, eliminating frequent maintenance. Its reliability has been proven in Xinjiang’s 1-million-sheep barn project (4,000 tons supplied, zero corrosion complaints).

2. JISCO’s End-to-End Expertise

As a global leader in Zn-Al-Mg technology, JISCO’s products comply with ISO 8353:2024 standards and offer full-chain services from material supply to engineering. For this project, JISCO customized the coating composition (11% aluminum, 3% magnesium) and co-developed modular assembly solutions, cutting construction timelines by 50%.

III. Economic and Social Impact

Cost Efficiency: A single 100,000-bird poultry house sees 25% lower costs, with payback periods reduced from 10 to 6 years.

Sustainability: 90% less steel waste and 120 tons of CO2 reduction annually per farm, aligning with China’s carbon peaking goals.

Industry Leadership: Recognized as a “Modern Farming Facility Demonstration Case” by the Ministry of Agriculture, the project drives industry standards like Technical Specifications for Zn-Al-Mg Steel Structures in Livestock Facilities.

IV. Leadership Vision and Future Plans

Mr. Pan Weihua, Chairman of Huarida Group, stated:

“This collaboration is a strategic move in our ‘Agriculture + New Energy’ dual-track strategy. Combining JISCO’s advanced materials with our smart solutions will redefine farming infrastructure standards. Over the next three years, we aim to deploy 500 Zn-Al-Mg poultry houses nationwide, covering layers, broilers, and breeding stock